Nissan Versa (N17): P0102, P0103 MAF sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | Trouble diagnosis name | DTC detecting condition | Possible cause |

| P0102 | Mass air flow sensor circuit low input | An excessively low voltage from the sensor is sent to ECM. |

|

| P0103 | Mass air flow sensor circuit high input | An excessively high voltage from the sensor is sent to ECM. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

Which DTC is detected?

P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P0102

- Start engine and wait at least 5 seconds.

- Check DTC.

Is DTC detected?

YES >> Go to EC183, "Diagnosis Procedure".

NO >> INSPECTION END

3.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P0103I

- Turn ignition switch ON and wait at least 5 seconds.

- Check DTC.

Is DTC detected?

YES >> Go to EC, "Diagnosis Procedure".

NO >> GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE FOR DTC P0103II

- Start engine and wait at least 5 seconds.

- Check DTC.

Is DTC detected?

YES >> Go to EC, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.INSPECTION START

Confirm the detected DTC.

Which DTC is detected?

P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.CHECK INTAKE SYSTEM

Check the following for connection.\

- Air duct

- Vacuum hoses

- Intake air passage between air duct to intake manifold

Is the inspection result normal?

YES >> GO TO 3.

NO >> Reconnect the parts.

3.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E. Refer to Ground Inspection in GI, "Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace ground connection.

4.CHECK MAF SENSOR POWER SUPPLY CIRCUIT

- Disconnect mass air flow (MAF) sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between MAF sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK MAF SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between MAF sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK MAF SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between MAF sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK MASS AIR FLOW SENSOR

Refer to EC, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 8.

NO >> Replace mass air flow sensor. Refer to EM, "Removal and Installation".

8.CHECK INTERMITTENT INCIDENT

Refer to GI, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK MASS AIR FLOW SENSORI

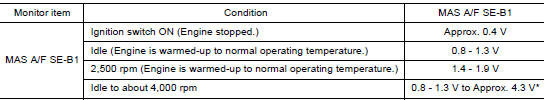

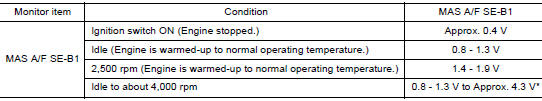

With CONSULT

With CONSULT

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Start engine and warm it up to normal operating temperature.

- Connect CONSULT and select "DATA MONITOR" mode of "ENGINE".

- Select "MAS A/F SEB1" and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

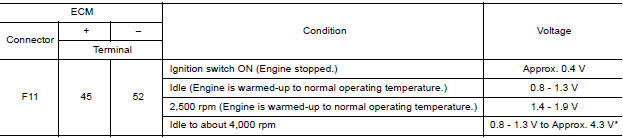

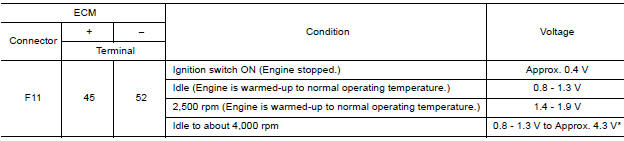

Without CONSULT

Without CONSULT

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Start engine and warm it up to normal operating temperature.

- Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK FOR THE CAUSE OF UNEVEN AIR FLOW THROUGH MASS AIR FLOW SENSOR

- Turn ignition switch OFF.

- Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system parts

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK MASS AIR FLOW SENSORII

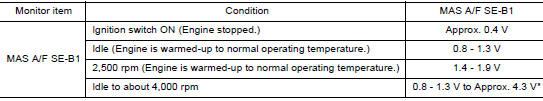

With CONSULT

With CONSULT

- Repair or replace malfunctioning part.

- Start engine and warm it up to normal operating temperature.

- Connect CONSULT and select "DATA MONITOR" mode of "ENGINE".

- Select "MAS A/F SEB1" and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

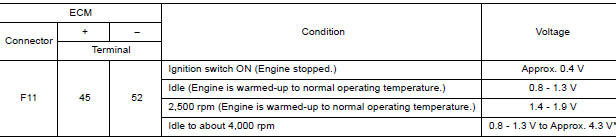

Without CONSULT

Without CONSULT

- Repair or replace malfunctioning part.

- Start engine and warm it up to normal operating temperature.

- Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK MASS AIR FLOW SENSORIII

With CONSULT

With CONSULT

- Turn ignition switch OFF.

- Disconnect mass air flow sensor harness connector and reconnect it again.

- Start engine and warm it up to normal operating temperature.

- Connect CONSULT and select "DATA MONITOR" mode of "ENGINE".

- Select "MAS A/F SEB1" and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT

Without CONSULT

- Turn ignition switch OFF.

- Disconnect mass air flow sensor harness connector and reconnect it again.

- Start engine and warm it up to normal operating temperature.

- Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Clean or replace mass air flow sensor. Refer to EM, "Removal and Installation".

Other materials:

Push-button ignition switch (if so equipped)

WARNING

Do not operate the push-button ignition

switch while driving the vehicle except in

an emergency. (The engine will stop when

the ignition switch is pushed 3 consecutive

times in quick succession or the ignition

switch is pushed and held for more

than 2 seconds.) If the engine stops ...

Throttle valve closed position

learning

Description

Throttle Valve Closed Position Learning is a function of ECM to learn the

fully closed position of the throttle

valve by monitoring the throttle position sensor output signal. It must be

performed each time harness connector

of electric throttle control actuator or ECM is discon ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.009

P0101 MAF sensor

P0101 MAF sensor