Nissan Versa (N17): P0101 MAF sensor

DTC Logic

DTC DETECTION LOGIC

NOTE: If DTC P0101 is displayed with other DTC, first perform the trouble diagnosis for other DTC.

| DTC No. | Trouble diagnosis name (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0101 | MAF SEN/CIRCUITB1 [Mass air flow (MAF) sensor circuit range/performance] |

|

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC CONFIRMATION PROCEDURE has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and warm it up to normal operating temperature.

- Drive the vehicle for at least 5 seconds under the following conditions: CAUTION: Always drive vehicle at safe speed.

NOTE:

- The gear must be fixed while driving the vehicle.

- Keep the accelerator pedal as steady as possible during cruising.

3. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC178, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK INTAKE SYSTEM

Check the following for connection.

- Air duct

- Vacuum hoses

- Intake air passage between air duct and intake manifold

Is the inspection result normal?

YES >> GO TO 2.

NO >> Reconnect the parts.

2.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

Check ground connection E. Refer to Ground Inspection in GI, "Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace ground connection.

3.CHECK MASS AIR FLOW (MAF) SENSOR POWER SUPPLY CIRCUIT

- Disconnect MAF sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between MAF sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

- Harness connectors E, F

- Harness for open or short between mass air flow sensor and ECM

- Harness for open or short between mass air flow sensor and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK MAF SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between MAF sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK MAF SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between MAF sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK INTAKE AIR TEMPERATURE SENSOR

Check the intake air temperature sensor. Refer to EC, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 8.

NO >> Replace MAF sensor (with intake air temperature sensor). Refer to EM, "Removal and Installation".

8.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Check the EVAP control system pressure sensor. Refer to EC, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace EVAP control system pressure sensor. Refer to FL, "Removal and Installation".

9.CHECK MAF SENSOR

Check the MAF sensor. Refer to EC, "Component Inspection".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI, "Intermittent Incident".

NO >> Replace MAF sensor. Refer to EM, "Removal and Installation".

Component Inspection

1.CHECK MASS AIR FLOW SENSORI

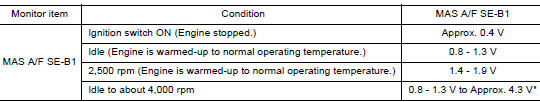

With CONSULT

With CONSULT

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Start engine and warm it up to normal operating temperature.

- Connect CONSULT and select "DATA MONITOR" mode of "ENGINE".

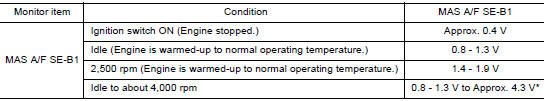

- Select "MAS A/F SEB1" and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

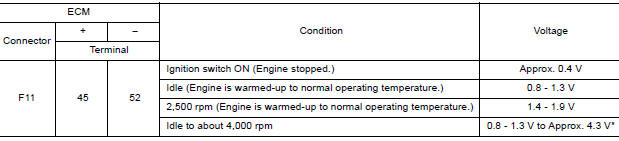

Without CONSULT

Without CONSULT

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Start engine and warm it up to normal operating temperature.

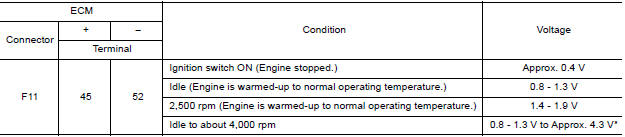

- Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK FOR THE CAUSE OF UNEVEN AIR FLOW THROUGH MASS AIR FLOW SENSOR

- Turn ignition switch OFF.

- Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system parts

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK MASS AIR FLOW SENSORII

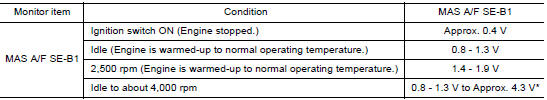

With CONSULT

With CONSULT

- Repair or replace malfunctioning part.

- Start engine and warm it up to normal operating temperature.

- Connect CONSULT and select "DATA MONITOR" mode of "ENGINE".

- Select "MAS A/F SEB1" and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

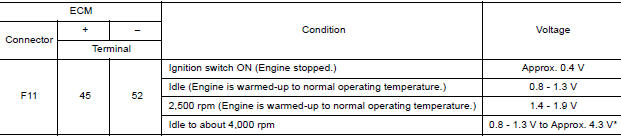

Without CONSULT

Without CONSULT

- Repair or replace malfunctioning part.

- Start engine and warm it up to normal operating temperature.

- Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK MASS AIR FLOW SENSORIII

With CONSULT

With CONSULT

- Turn ignition switch OFF.

- Disconnect mass air flow sensor harness connector and reconnect it again.

- Start engine and warm it up to normal operating temperature.

- Connect CONSULT and select "DATA MONITOR" mode of "ENGINE".

- Select "MAS A/F SEB1" and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT

Without CONSULT

- Turn ignition switch OFF.

- Disconnect mass air flow sensor harness connector and reconnect it again.

- Start engine and warm it up to normal operating temperature.

- Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Clean or replace mass air flow sensor. Refer to EM, "Removal and Installation".

Other materials:

Heater and Air Conditioner (manual)

WARNING

The air conditioner cooling function operates

only when the engine is running.

Do not leave children or adults who

would normally require the assistance

of others alone in your vehicle. Pets

should also not be left alone. They

could accidentally injure themselves or

others ...

Oil pan (upper) and oil strainer

Exploded View

1. Rear oil seal 2. Oring 3. Oil pan (upper)

4. Oil pump chain tensioner (for oil

pump drive chain)

5. Oil pump drive chain 6. Crankshaft key

7. Crankshaft sprocket 8. Oil pump sprocket 9. Oil pump

10. Oring 11. Oring 12. Oil pan drain plug

13. Drain plug washer 14. Oil pan ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0081

P0078 EVT control solenoid valve

P0078 EVT control solenoid valve