Nissan Versa (N17): Trunk lid opener switch

Component Function Check

1.CHECK FUNCTION

- Select TRUNK of BCM using CONSULT.

- Select TR/BD OPEN SW in DATA MONITOR mode.

- Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Trunk lid switch is OK.

NO >> Refer to DLK "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to DLK "TRUNK LID OPENER SYSTEM : Wiring Diagram".

1.CHECK TRUNK LID OPENER INPUT SIGNAL

- Turn ignition switch OFF.

- Disconnect trunk lid switch connector.

- Check signal between trunk lid switch harness connector and ground using

oscilloscope.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK TRUNK LID OPENER SWITCH CIRCUIT

- Disconnect BCM connector.

- Check continuity between BCM harness connector and trunk lid switch

harness connector.

- Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK TRUNK LID SWITCH GROUND CIRCUIT

Check continuity between trunk lid switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK TRUNK LID SWITCH

Refer to DLK "Component Function Check".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace trunk lid switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI "Intermittent Incident".

>> Inspection End.

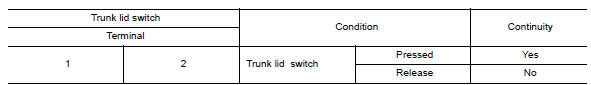

Component Inspection

1.CHECK TRUNK LID SWITCH

- Turn ignition switch OFF.

- Disconnect trunk lid switch connector.

- Check continuity between trunk lid switch terminals.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace trunk lid switch.

Trunk lid opener actuator

Trunk lid opener actuator

Component Function Check 1.CHECK FUNCTION Select INTELLIGENT KEY of BCM using CONSULT. Select TRUNK/GLASS HATCH in ACTIVE TEST mode. Touch OPEN to check that it works normally. Is the insp ...

Trunk lamp switch

Description Detects trunk open/close condition. Component Function Check 1.CHECK FUNCTION With CONSULT Check TRNK/HAT MNTR in Data Monitor mode with CONSULT. Is the inspection ...

Other materials:

Clutch master cylinder

Exploded View

1. Reservoir hose 2. Master cylinder

Removal and Installation

CAUTION:

Do not spill clutch fluid onto painted surfaces. If fluid spills,

wipe up immediately and wash the

affected area with water.

Do not disassemble clutch master cylinder.

NOTE:

When removing compo ...

Line pressure control

LINE PRESSURE CONTROL : System Description

SYSTEM DIAGRAM

DESCRIPTION

Highly accurate line pressure control (secondary pressure control) reduces

friction for improvement of fuel

economy.

Normal Oil Pressure Control

Appropriate line pressure and secondary pressure suitable for driving

c ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0097