Nissan Versa (N17): P0705 Transmission range switch A

DTC Logic

DTC DETECTION LOGIC

| DTC | Trouble diagnosis name | DTC detection condition | Possible causes |

| P0705 | Transmission Range Sensor "A" Circuit Malfunction (PRNDL input) | The following diagnosis conditions

are met and 2 or more position

signals are ON at the

same time for 5 seconds or

more. - Diagnosis condition - TCM power supply voltage: 10 V <TCM power supply voltage <16 V |

|

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn the ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Turn ignition switch ON.

- Shift the selector lever to the entire position from P to 1. (Hold the selector lever at each position for 10 seconds or more.)

- Check the first trip DTC.

Is "P0705" detected?

YES >> Go to TM, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

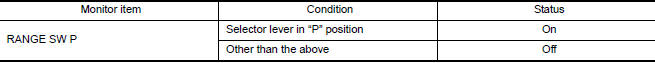

1.CHECK TCM INPUT SIGNALS

With CONSULT

- Turn ignition switch ON.

- Select "TRANSMISSION" "DATA MONITOR".

- Select the "D position switch", "N position switch", "R position switch", "P position switch", "2 position switch", and "1 position switch".

- Shift the selector lever to the entire position from P to 1, and check

the ON/OFF operation of each monitor

item.

Without CONSULT.

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Turn ignition switch ON.

- Shift the selector lever to the entire position from P to 1, and check

the voltage between the TCM harness

connector terminal and ground.

Is the check result normal?

YES >> Check intermittent incident. Refer to GI, "Intermittent Incident".

NO-1 [D position SW is "On" when selector is not in D position. (Or, connector terminal 4 is at 10 - 16 V.)]>> GO TO 2.

NO-2 [N position SW is "On" when selector is not in N position. (Or, connector terminal 5 is at 10 - 16 V.)]>> GO TO 4.

NO-3 [R position SW is "On" when selector is not in R position. (Or, connector terminal 6 is at 10 - 16 V.)]>> GO TO 6.

NO-4 [P position SW is "On" when selector is not in P position. (Or, connector terminal 7 is at 10 - 16 V.)]>> GO TO 8.

NO-5 [2 position SW is "On" when selector is not in 2 position. (Or, connector terminal 3 is at 10 - 16 V.)]>> GO TO 10.

NO-6 [1 position SW is "On" when selector is not in 1 position. (Or, connector terminal 2 is at 10 - 16 V.)]>> GO TO 12.

2.CHECK D POSITION SW CIRCUIT (CHECK 1)

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Check the continuity between the TCM harness connector terminals.

Is the check result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK D POSITION SW CIRCUIT (CHECK 2)

- Disconnect the transmission range switch connector.

- Turn the ignition switch ON.

- Check the voltage between the TCM harness connector and ground.

Is the check result normal?

YES >> GO TO 14.

NO >> Repair or replace the malfunctioning parts.

4.CHECK N POSITION SW CIRCUIT (CHECK 1)

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Check the continuity between the TCM harness connector terminals.

Is the check result normal?

YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

5.CHECK N POSITION SW CIRCUIT (CHECK 2)

- Disconnect the transmission range switch connector.

- Turn ignition switch ON.

- Check the voltage between the TCM harness connector and ground.

Is the check result normal?

YES >> GO TO 14.

NO >> Repair or replace the malfunctioning parts.

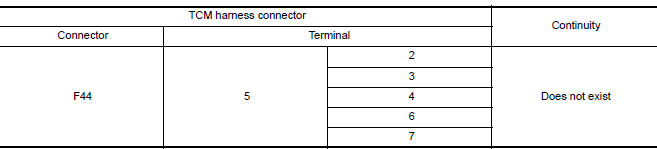

- 6.CHECK P POSITION SW CIRCUIT (CHECK 1)

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Check the continuity between the TCM harness connector terminals.

Is the check result normal?

YES >> GO TO 7.

NO >> Repair or replace the malfunctioning parts.

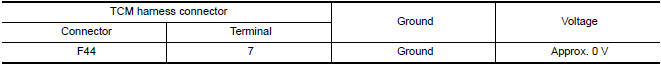

7.CHECK P POSITION SW CIRCUIT (CHECK 2)

- Disconnect the transmission range switch connector.

- Turn ignition switch ON.

- Check the voltage between the TCM harness connector and ground.

Is the check result normal?

YES >> GO TO 14.

NO >> Repair or replace the malfunctioning parts.

8.CHECK R POSITION SW CIRCUIT (CHECK 1)

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Check the continuity between the TCM harness connector terminals.

Is the check result normal?

YES >> GO TO 9.

NO >> Repair or replace the malfunctioning parts.

9.CHECK R POSITION SW CIRCUIT (CHECK 2)

- Disconnect the transmission range switch connector.

- Turn ignition switch ON.

- Check the voltage between the TCM harness connector and ground.

Is the check result normal?

YES >> GO TO 14.

NO >> Repair or replace the malfunctioning parts.

10.CHECK 2 POSITION SW CIRCUIT (CHECK 1)

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Check the continuity between the TCM harness connector terminals.

Is the check result normal?

YES >> GO TO 11.

NO >> Repair or replace the malfunctioning parts.

11.CHECK 2 POSITION SW CIRCUIT (CHECK 2)

- Disconnect the transmission range switch connector.

- Turn ignition switch ON.

- Check the voltage between the TCM harness connector and ground.

Is the check result normal?

YES >> GO TO 14.

NO >> Repair or replace the malfunctioning parts.

12.CHECK 1 POSITION SW CIRCUIT (CHECK 1)

- Turn ignition switch OFF.

- Disconnect the TCM connector.

- Check the continuity between the TCM harness connector terminals.

Is the check result normal?

YES >> GO TO 13.

NO >> Repair or replace the malfunctioning parts.

13.CHECK 1 POSITION SW CIRCUIT (CHECK 2)

- Disconnect the transmission range switch connector.

- Turn ignition switch ON.

- Check the voltage between the TCM harness connector and ground.

Is the check result normal?

YES >> GO TO 14.

NO >> Repair or replace the malfunctioning parts.

14.CHECK TRANSMISSION RANGE SWITCH

Check the transmission range switch. Refer to TM, "Component Inspection (Transmission Range Switch)".

Is the check result normal?

YES >> Check intermittent incident. Refer to GI, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

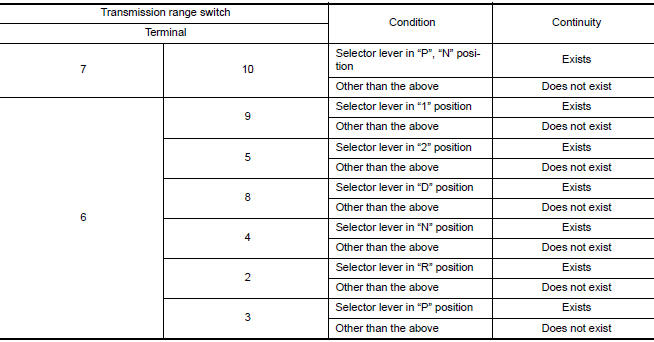

Component Inspection (Transmission Range Switch)

1.CHECK TRANSMISSION RANGE SWITCH

Check the continuity between the transmission range switch connector

terminals.

Is the check result normal?

YES >> INSPECTION END

NO >> There is a malfunction of the transmission range switch. Replace the transaxle assembly. Refer to TM, "Removal and Installation".

P062F EEPROM

P062F EEPROM

Description TCM checks the value read in FLASH ROM at ignition switch ON, and judges if there is writing failure to FLASH ROM or malfunction of FLASH ROM. DTC Logic DTC DETECTION LOGIC ...

P0706 Transmission range sensor A

DTC Logic DTC DETECTION LOGIC DTC Trouble diagnosis name DTC detection condition Possible causes P0706 Transmission Range Sensor "A" Circuit Range/Performance The ...

Other materials:

Bluetooth Hands-Free Phone System with Navigation System (if so equipped)

WARNING

Use a phone after stopping your vehicle

in a safe location. If you have to use a

phone while driving, exercise extreme

caution at all times so full attention may

be given to vehicle operation.

If you are unable to devote full attention

to vehicle operation while talking on

...

Timing chain

Exploded View

1. Timing chain slack guide 2. Timing chain tensioner 3. Camshaft sprocket

(EXH)

4. Camshaft sprocket (INT) 5. Plug 6. Front oil seal

7. Crankshaft pulley 8. Crankshaft pulley bolt 9. Front cover

10. Crankshaft sprocket 11. Crankshaft sprocket key 12. Oil pump sprocket

13. O ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0096