Nissan Versa Sedan Service ManualEngine » Starting system (STR) » Starter motor

Nissan Versa Sedan Service ManualEngine » Starting system (STR) » Starter motor

Inspection and Adjustment

Inspection and Adjustment

INSPECTION

Magnetic Switch Check

- Disconnect the battery cable from the negative terminal. Refer to PG "Removal and Installation".

- Disconnect "M" terminal of starter motor.

- Test continuity between "S" terminal (A) and switch body.

(B): "B" terminal (C): "C" terminal

- Replace magnetic switch if continuity does not exist.

4. Test continuity between "S" terminal (A) and "M" terminal (C). (B): "B" terminal

- Replace magnetic switch if continuity does not exist.

Pinion/Clutch Check

- Inspect pinion teeth.

- Replace pinion if teeth are worn or damaged. (Also check condition of ring gear teeth.)

- Inspect planetary gear teeth.

- Replace planetary gear if teeth are worn or damaged. (Also check condition of armature shaft gear teeth.)

- Check to see if pinion locks in one direction and rotates smoothly in the opposite direction.

- Replace pinion assembly if it is locked or rotated in both directions or unusual resistance is evident.

Brush Check

- Check brushes for excessive wear.

Minimum length of brush : Refer to STR

- Replace brush holder assembly if the measurement value is less than the specified value.

Brush Spring Check

- Check brush spring tension with brush spring detached from brush.

Spring tension (with new brush) : Refer to

- Replace brush holder assembly if the measurement value is less than the specified value.

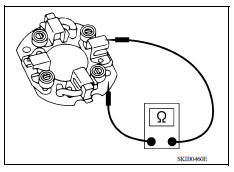

Brush Holder Check

- Perform insulation test between brush holder (positive side) and its base (negative side).

- Replace brush holder assembly if continuity does not exist.

- Check brush to see if it moves smoothly.

- If sliding surface is dirty, clean it.

- If brush holder is bent or damaged, replace brush holder assembly.

Yoke Check

Magnet is secured to yoke by bonding agent. Check magnet for cracks and to ensure it is secured to yoke. If damaged, replace yoke assembly.

CAUTION: Do not clamp yoke in a vise or strike it with a hammer.

Armature Check

- Test continuity between two segments side by side.

- Replace armature assembly if continuity does not exist (1).

- Test insulation between each commutator bar and shaft.

- Replace armature assembly if continuity exists (2).

3. Check commutator surface.

- Clean commutator with No. 500 - 600 emery paper.

4. Check diameter of commutator.

- Replace armature assembly if the measurement value is less than the specified value.

Commutator minimum diameter : Refer to STR

5. Check depth of insulating mold from commutator surface.

- Undercut to 0.5 to 0.8 mm (0.020 to 0.031 in) if the depth is 0.2 mm (0.008 in) or less.

PINION PROTRUSION LENGTH ADJUSTMENT

1. Apply battery power to the magnetic switch.

2. Push the pinion back to remove the slack and measure clearance "L" between the front edge of the pinion and the pinion stopper.

Clearance "L" : Refer to STR

3. If the measurement value is not within specifications, adjust using the adjustment plate.

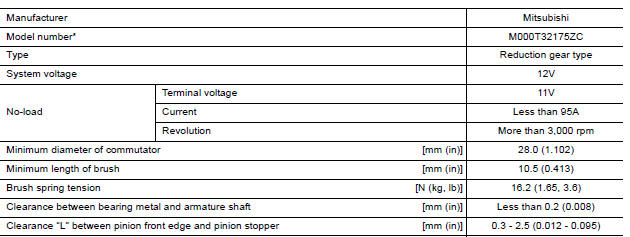

SERVICE DATA AND SPECIFICATIONS (SDS)

Starter Motor