Nissan Versa Sedan Service ManualBrakes » Brake system (BR) » Brake caliper assembly

Nissan Versa Sedan Service ManualBrakes » Brake system (BR) » Brake caliper assembly

Brake caliper assembly : Disassembly and

Assembly

Brake caliper assembly : Disassembly and Assembly

DISASSEMBLY

NOTE: Do not remove the torque member, pad return springs, brake pads and pad retainers when disassembling and assembling the brake caliper assembly.

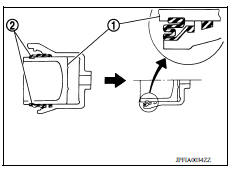

- Place a wooden block as shown, and blow air from union bolt

mounting hole to remove piston and piston boot.

WARNING: Do not get fingers caught between the piston and wooden block.

2. Remove piston seal from cylinder body using suitable tool.

CAUTION:

- Be careful not to damage a cylinder inner wall.

- Do not reuse piston seal.

3. Remove bleeder valve and cap.

4. Perform inspection after disassembly.

INSPECTION AFTER DISASSEMBLY

Caliper

Check the inner wall of caliper for corrosion, wear, and damage. Replace as necessary.

CAUTION: Clean the caliper using new brake fluid. Do not use mineral oils such as gasoline or kerosene.

Torque Member

Check torque member for wear, cracks, and damage. Replace as necessary.

Piston

Check the piston surface for corrosion, wear, and damage. Replace as necessary.

CAUTION: The piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin Bolt, Sliding Pin Boot

Check the sliding pin, sliding pin bolt, and sliding pin boot for wear, damage, and cracks. Replace as necessary.

ASSEMBLY

- Install bleeder valve and cap.

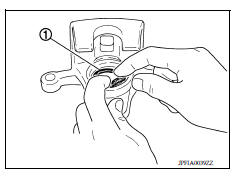

- Apply brake fluid to piston seal (1), and install to groove in cylinder body.

CAUTION: Do not reuse piston seal.

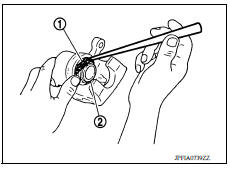

3. Apply rubber grease to piston boot (1). Cover the piston (2) end with piston boot, and then install cylinder side lip on piston boot securely into a groove on cylinder body.

CAUTION: Do not reuse piston boot.

4. Push piston (1) into cylinder body by hand and push piston boot (2) piston-side lip into the piston groove.

CAUTION: Press the piston evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.