Nissan Versa Sedan Service ManualVentilation, heater & air conditioner » Heater & air conditioning control system (HAC) » Precautions

Nissan Versa Sedan Service ManualVentilation, heater & air conditioner » Heater & air conditioning control system (HAC) » Precautions

Service Equipment

Service Equipment

RECOVERY/RECYCLING EQUIPMENT

Follow the manufacturer's instructions for machine operation and machine maintenance. Do not introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions for tester operation and tester maintenance.

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the specified oil for HFC-134a (R-134a) A/C systems. The vent side of the vacuum pump is exposed to atmospheric pressure so the vacuum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve situated near the hose-to-pump connection, as follows.

- Usually vacuum pumps have a manual isolator valve as part of the pump. Close this valve to isolate the service hose from the pump.

- For pumps without an isolator, use a hose equipped with a manual shut-off valve near the pump end. Close the valve to isolate the hose from the pump.

- If the hose has an automatic shut off valve, disconnect the hose from the pump: as long as the hose is connected, the valve is open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close under a no vacuum condition. Such valves may restrict the pump's ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-134a or 134a. Make sure the gauge set has 1/2″-16 ACME threaded connections for service hoses. Confirm the set has been used only with refrigerant HFC- 134a (R-134a) along with specified oil.

SERVICE HOSES

Be certain that the service hoses display the markings described (colored hose with black stripe). All hoses must include positive shutoff devices (either manual or automatic) near the end of the hoses opposite the manifold gauge.

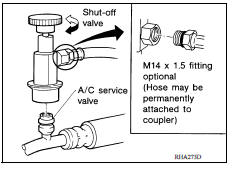

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

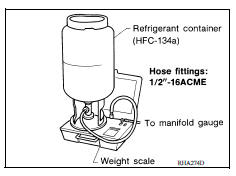

WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and specified oils have been used with the weight scale. If the weight scale controls refrigerant flow electronically, the hose fitting must be 1/2"- 16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder's top valve when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an electronic scale or of quality recycle/recharge equipment.

PREPARATION

Special Service Tool

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tool

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts Location

1. IPDM E/R 2. ECM 3. BCM (view with instrument panel removed) 4. Front air control 5. A/C compressor 6. Front blower motor (view with A/C unit assembly removed) 7. Front blower motor resistor (view with A/C unit assembly removed) 8. Thermo control amp. (view with A/C unit assembly removed) 9. Refrigerant pressure sensor 10. Fuse block (J/B) 11. Blower relay

Component Description

| Component | Description |

| A/C compressor | Vaporized refrigerant is drawn into the A/C compressor from the evaporator, where it is compressed to a high pressure, high temperature vapor. The hot, compressed vapor is then discharged to the condenser. |

| BCM | The BCM receives the fan ON and A/C ON signals from the front air control and sends a compressor ON request to the ECM. |

| ECM | The ECM sends a compressor ON request to the IPDM E/R based on the status of engine operation and load as well as refrigerant pressure information. If all the conditions are met for A/C operation, the ECM transmits the compressor ON request to the IPDM E/R. |

| Fuse Block (J/B) | Located in the passenger compartment, behind the left lower IP, the Fuse Block (J/B) contains the front blower motor relay and several fuses required for the air conditioner control system. |

| Front air control | The front air control controls the operation of the A/C and heating system. |

| Front blower motor | The front blower motor varies the speed at which the air flows through the ventilation system. |

| Front blower motor relay | The front blower motor relay controls the flow of current to fuse 20, 21 and 22 in the Fuse Block (J/ B). The relay is connected directly to ground, and is energized when the ignition switch is in the ON or START position. |

| Front blower motor resistor | Ground for the blower is supplied through blower resistor and the blower speed switch. As the switch is moved from position 1 through 5, more current is allowed to flow through the motor, for a higher speed. This is because less resistors are in the path as the switch is moved to a higher position. When the switch is on the highest position, all resistors are bypassed. |

| IPDM E/R | A/C relay is integrated in IPDM E/R. IPDM E/R operates A/C relay when receiving A/C compressor request signal from ECM via CAN communication line. |

| Refrigerant pressure sensor | Refer to EC "Refrigerant Pressure Sensor". |

| Thermo control amp. | Thermo control amp. is composed of thermistor and amplifier. When the A/C switch signal is received from the front air control, the thermo control amp. transmits the A/C ON signal to the BCM according to evaporator fin temperature. When the thermistor detecting temperature of the air that passes through evaporator is extremely low, the thermo control amp. sends the A/C OFF signal to BCM, and stops the compressor. |

SYSTEM