Nissan Versa (N17): Precautions in repairing high strength steel

High Strength Steel (HSS)

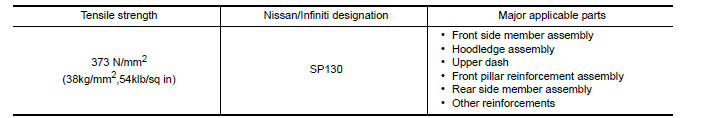

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength

steel are described below:

SP130 is the most commonly used HSS.

Read the following precautions when repairing HSS:

1. Additional points to consider

- The repair of reinforcements (such as side members) by heating

is not recommended since it may weaken the component.

When heating is unavoidable, do not heat HSS parts above 550C (1,022F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropriate.)

- When straightening body panels, use caution in pulling any HSS panel. Because HSS is very strong, pulling may cause deformation in adjacent portions of the body. In this case, increase the number of measuring points, and carefully pull the HSS panel.

- When cutting HSS panels, avoid gas (torch) cutting if possible.

Instead, use a saw to avoid weakening surrounding areas due to heat. If gas (torch) cutting is unavoidable, allow a minimum margin of 50 mm (1.97in).

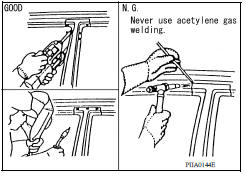

- When welding HSS panels, use spot welding whenever possible

in order to minimize weakening surrounding areas due to

heat.

If spot welding is impossible, use M.I.G. welding. Do not use gas (torch) welding because it is inferior in welding strength.

- The spot weld on HSS panels is harder than that of an ordinary

steel panel.

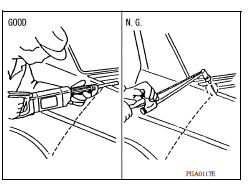

Therefore, when cutting spot welds on a HSS panel, use a low speed high torque drill (1,000 to 1,200 rpm) to increase drill bit durability and facilitate the operation.

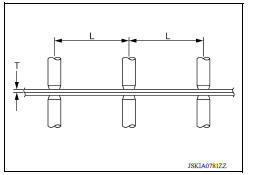

2. Precautions in spot welding HSS

This work should be performed under standard working conditions.

Always note the following when spot welding HSS:

- The electrode tip diameter must be sized properly according to the metal thickness.

- The panel surfaces must fit flush to each other, leaving no gaps.

- Follow the specifications for the proper welding pitch.

Handling of Ultra High Strength Steel Plate Parts

PROHIBITION OF CUT AND CONNECTION

Do not cut and join the lower lock pillar reinforcement (center pillar reinforcement inside frame parts) because its material is high strength steel plate (ultra high strength steel plate).

The center pillar reinforcement must be replaced if this part is damaged.

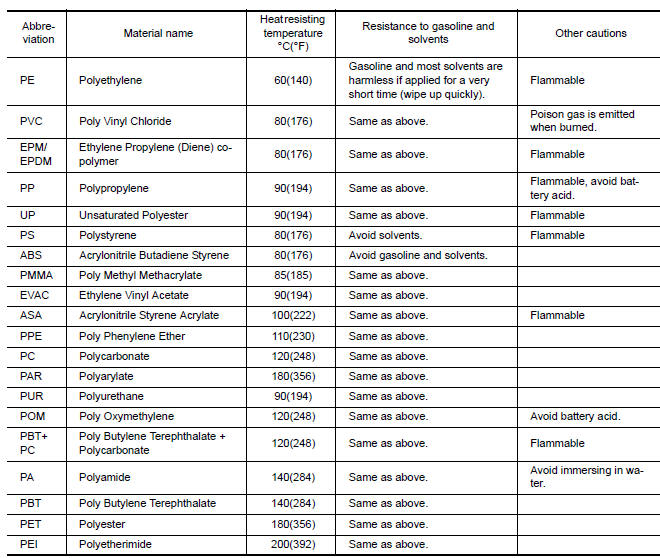

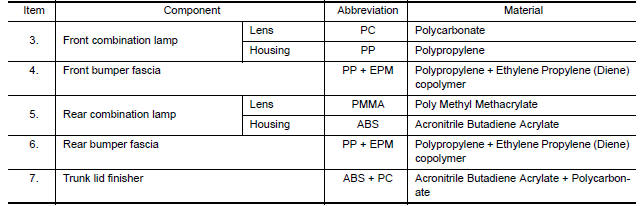

HANDLING PRECAUTIONS FOR PLASTICS

Precautions For Plastics

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics (influence of heat and solvent) and remove them if necessary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials, characteristics.

LOCATION OF PLASTIC PARTS

PREPARATION

Precautions

Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER" The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT PRE-TENSIONER", us ...

Repairing material

Foam Repair During factory assembly, foam insulators are installed in certain body panels and locations around the vehicle. Use the following procedure(s) to replace any factory-installed foam ...

Other materials:

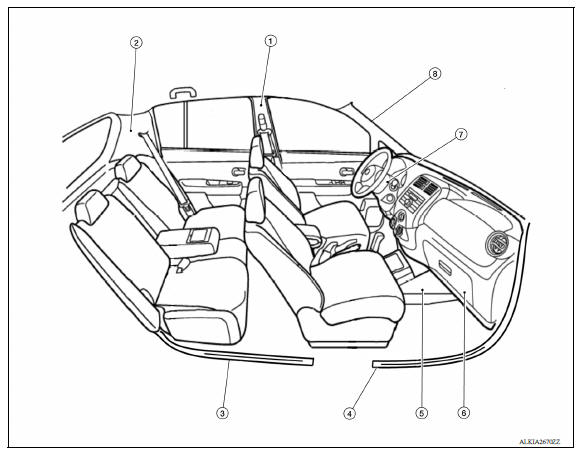

Instrument panel

1. Headlight/turn signal switch/fog light

switch (if so equipped)

2. Driver's supplemental air bag (P. 1-39)

Horn

3. Meters and gauges. Warning and indicator lights

4. Wiper and washer switch

5. Vents

6. Rear window defroster switch

7. Front passenger air bag status light

8. Hazard warn ...

Fuel-filler door

Opener operation

The fuel-filler door release is located below the

instrument panel. To open the fuel-filler door, pull

the release. To lock, close the fuel-filler door

securely.

Fuel-filler cap

WARNING

Gasoline is extremely flammable and

highly explosive under certain conditions.

...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0077