Nissan Versa (N17): Precautions

Precaution for supplemental restraint system (SRS) "Air bag" and "Seat belt pre-tensioner"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT PRE-TENSIONER", used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Manual.

WARNING:

- To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

- Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see the SR section.

- Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

- When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing serious injury.

- When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for Procedure without Cowl Top Cover

When performing the procedure after removing cowl top cover, cover the lower end of windshield with urethane, etc to prevent damage to windshield.

Precaution for TCM and Transaxle Assembly Replacement

CAUTION:

- To replace TCM, refer to TM "Description".

- To replace transaxle assembly, refer to TM "Description".

Precaution for G Sensor Removal/Installation or Replacement

CAUTION: To remove/install or replace G sensor, refer to TM "Description".

General precautions

- Turn ignition switch OFF and disconnect the battery cable from the negative terminal before connecting or disconnecting the CVT assembly harness connector. Because battery voltage is applied to TCM even if ignition switch is turned OFF.

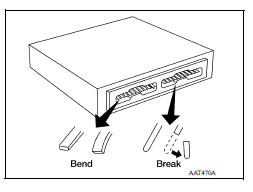

- When connecting or disconnecting pin connectors into or

from TCM, do not damage pin terminals (bend or break).

Check that there are not any bends or breaks on TCM pin terminal, when connecting pin connectors.

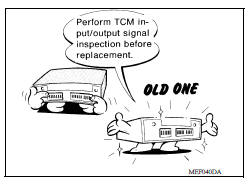

- Perform TCM input/output signal inspection and check

whether TCM functions normally or not before replacing TCM.

Refer to TM "Reference Value".

- Perform "DTC (Diagnostic Trouble Code) CONFIRMATION

PROCEDURE".

If the repair is completed DTC should not be displayed in the "DTC CONFIRMATION PROCEDURE".

- Always use the specified brand of CVT fluid. Refer to MA "Fluids and Lubricants".

- Use lint-free paper not cloth rags during work.

- Dispose of the waste oil using the methods prescribed by law, ordinance, etc. after replacing the CVT fluid.

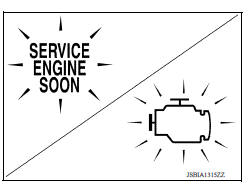

On board diagnosis (OBD) System of CVT and Engine

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the driver of a malfunction causing emission deterioration.

CAUTION:

- Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal before any repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will cause the MIL to light up.

- Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease, dirt, bent terminals, etc.)

- Be sure to route and secure the harnesses properly after work. Interference of the harness with a bracket, etc. may cause the MIL to light up due to a short circuit.

- Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

- Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and ECM before returning the vehicle to the customer.

Removal and installation procedure for CVT Unit connector

REMOVAL

- Rotate bayonet ring (A) counterclockwise. Pull out CVT unit harness connector (B) upward and remove it.

INSTALLATION

- Align marking (A) on CVT unit harness connector terminal with marking (B) on bayonet ring. Insert CVT unit harness connector.

- Rotate bayonet ring clockwise.

3. Rotate bayonet ring clockwise until marking (A) on CVT unit harness connector terminal body is aligned with the slit (B) on bayonet ring as shown in the figure (correctly fitting condition).

CAUTION:

- Securely align marking (A) on CVT unit harness connector terminal body with bayonet ring slit (B). Then, be careful not to make a half fit condition as shown in the figure.

- Do not mistake the slit of bayonet ring for other dent portion.

PREPARATION

Special Service Tools

*: The O-ring as an unit part is set as a SST.

Commercial Service Tools

Service data and specifications

(SDS)

Service data and specifications

(SDS)

General Specification CAUTION: Use only Genuine NISSAN Matic S ATF. Do not mix with other ATF. Using ATF other than Genuine NISSAN Matic S ATF will cause deterioration of driv ...

Component parts

CVT CONTROL SYSTEM CVT CONTROL SYSTEM : Component Parts Location 1. IPDM E/R 2. TCM 3. Transmission range switch 4. Primary speed sensor 5. CVT unit 6. Output speed sensor 7. Secondary speed s ...

Other materials:

Clutch pedal

Exploded View

1. Clutch pedal 2. Pedal stopper rubber 3. Pedal pad

4. Clip 5. Clutch interlock switch

Removal and Installation

REMOVAL

Remove the instrument lower panel LH. Refer to IP, "Removal and

Installation".

Disconnect master cylinder rod end from clutch pedal.

D ...

Calibration of G Sensor

Description

TCM stores calibration data (inherent characteristic value) of G sensor to

provide accurate control. Therefore,

it is required to perform calibration of G sensor after the following work is

performed.

Removal/installation or replacement of G sensor

Replacement of TCM

Work ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0108