Nissan Versa (N17): Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as "AIR BAG" and "SEAT BELT PRE-TENSIONER", used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Manual.

WARNING:

- To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

- Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see the SR section.

- Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

- When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing serious injury.

- When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery and wait at least 3 minutes before performing any service.

Precaution for Procedure without Cowl Top Cover

When performing the procedure after removing cowl top cover, cover the lower end of windshield with urethane, etc to prevent damage to windshield.

Precaution for Servicing Doors and Locks

WARNING: Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should contact the electric medical equipment manufacturer for the possible influences before use.

- After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their operation.

- Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

- When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

- When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

- Protect the removed parts with a shop cloth and prevent them from being dropped.

- Replace a deformed or damaged clip.

- If a part is specified as a non-reusable part, always replace it with a new one.

- Be sure to tighten bolts and nuts securely to the specified torque.

- After installation is complete, be sure to check that each part works properly.

- Follow the steps below to clean components:

- Water soluble dirt:

- Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

- Then rub with a soft, dry cloth.

- Oily dirt:

- Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

- Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

- Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

PREPARATION

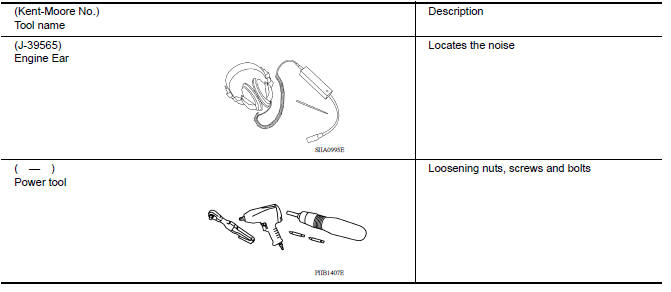

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools

SYSTEM DESCRIPTION

Body repair (BRM)

Body repair (BRM)

VEHICLE INFORMATION BODY EXTERIOR PAINT COLOR Body Exterior Paint Color M = Metallic, S = Solid, 2S = Solid and Clear, 2P = 2-stage Pearl, 3P = 3-Stage pearl, PM = Pearl metallic, t = Pri ...

Component parts

POWER DOOR LOCK SYSTEM POWER DOOR LOCK SYSTEM : Component Parts Location 1. BCM (shown with instrument panel removed) 2. Front door switch LH 3. Front door lock actuator LH 4. Front door l ...

Other materials:

Output speed sensor

Exploded View

1. Output speed sensor 2. O-ring 3. Transaxle assembly

Front

Removal and Installation

REMOVAL

Remove the front LH wheel and tire.

Disconnect the harness connector from output speed sensor.

Remove the output speed sensor.

Remove the O-ring from the output speed sens ...

Hazard function

Component Function Check

1.CHECK FUNCTION

Select INTELLIGENT KEY of BCM using CONSULT.

Select FLASHER in ACTIVE TEST mode.

Touch LH or RH to check that it works normally.

Is the inspection result normal?

YES >> Hazard warning lamp circuit is OK.

NO >> Refer to DLK "D ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0073