Nissan Versa (N17): P2101 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC P2101 is displayed with DTC P2100, first perform the trouble diagnosis for DTC P2100. Refer to EC, "DTC Logic".

- If DTC P2101 is displayed with DTC P2119, first perform the trouble diagnosis for DTC P2119. Refer to EC, "DTC Logic".

| DTC No. | Trouble diagnosis name | DTC detecting condition | Possible cause |

| P2101 | Electric throttle control performance | Electric throttle control function does not operate properly. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 11 V when engine is running.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 2 seconds.

- Start engine and let it idle for 5 seconds.

- Check DTC.

Is DTC detected?

YES >> Go to EC, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E15. Refer to Ground Inspection in GI, "Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT

- Turn ignition switch ON.

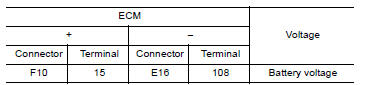

- Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 11.

NO >> GO TO 3.

3.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-I

- Turn ignition switch OFF.

- Check voltage between ECM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 4.

4.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-II

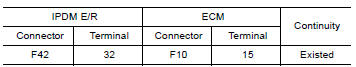

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector F42.

- Check the continuity between ECM harness connector and IPDM E/R harness

connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

- IPDM E/R connector F42

- Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK FUSE

- Disconnect 20 A fuse (No. 53) from IPDM E/R.

- Check 20 A fuse for blown.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Replace 20 A fuse.

7.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-III

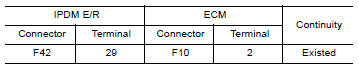

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector F42.

- Check the continuity between ECM harness connector and IPDM E/R harness

connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

- IPDM E/R connector F42

- Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK FUSE

- Disconnect 15 A fuse (No. 52) from IPDM E/R.

- Check 15 A fuse for blown.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Replace 15 A fuse.

10.CHECK INTERMITTENT INCIDENT

Refer to GI, "Intermittent Incident".

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS, "Removal and Installation" (WITH I-KEY) or PCS, "Removal and Installation" (WITHOUT I-KEY).

NO >> Repair or replace harness or connectors.

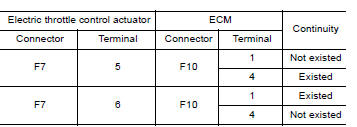

11.CHECK THROTTLE CONTROL MOTOR OUTPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

- Turn ignition switch OFF.

- Disconnect electric throttle control actuator harness connector.

- Disconnect ECM harness connector.

- Check the continuity between electric throttle control actuator harness

connector and ECM harness connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 12.

NO >> Repair or replace harness or connectors.

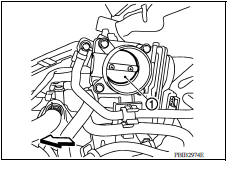

12.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

- Remove the intake air duct. Refer to EM, "Removal and Installation"

- Check if foreign matter is caught between the throttle valve (1) and the housing.

Vehicle front

Is the inspection result normal?

YES >> GO TO 13.

NO >> Remove the foreign matter and clean the electric throttle control actuator inside, and then perform throttle valve closed position learning. Refer to EC, "Work Procedure".

13.CHECK THROTTLE CONTROL MOTOR

Refer to EC, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 14.

NO >> GO TO 15.

14.CHECK INTERMITTENT INCIDENT

Refer to GI, "Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 15.

NO >> Repair or replace harness or connectors.

15.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

Replace malfunction electric throttle control actuator. Refer to EM, "Removal and Installation".

>> INSPECTION END

Component Inspection

1.CHECK THROTTLE CONTROL MOTOR

- Disconnect electric throttle control actuator harness connector.

- Check resistance between electric throttle control actuator terminals as

follows.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

Replace electric throttle control actuator. Refer to EM, "Removal and Installation".

>> INSPECTION END

Other materials:

P1212 TCS communication line

Description

This CAN communication line is used to control the smooth engine operation

during the TCS operation. Pulse

signals are exchanged between ECM and "ABS actuator and electric unit (control

unit)".

Be sure to erase the malfunction information such as DTC not only for "ABS

actuat ...

Trunk lid finisher

Exploded View

1. Trunk lid finisher 2. Emblem 3. Rear view camera (if equipped)

Pawl Clip

Removal and Installation

REMOVAL

1. Remove trunk lid finisher inner. Refer to INT "Removal and Installation".

2. Remove trunk lid finisher nuts.

3. Disconnect the harness connectors from ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0086

P2100, P2103 throttle control motor

relay

P2100, P2103 throttle control motor

relay