Nissan Versa (N17): Manual air conditioning system

MANUAL AIR CONDITIONING SYSTEM : System Diagram

MANUAL AIR CONDITIONING SYSTEM : System Description

- The manual air conditioning system is controlled by a sequence of functions from the front air control, BCM, ECM, and IPDM E/R.

- The fan speed of the front blower motor is changed by the combination of the fan control dial (fan switch) operation and blower resistor control.

|

Module/Function |

Door control | A/C request signal | Compressor control | Cooling fan control |

| Front air control | HAC | HAC | ||

| BCM | BCS or BCS | |||

| ECM | HAC | EC | ||

| IPDM E/R | HAC | EC |

Manual air conditioning system : Compressor Control

DESCRIPTION

- When A/C switch signal is received from front air control, the thermo control amp. transmits A/C ON signal to the BCM according to evaporator fin temperature.

- When the front blower motor is operated, the front air control transmits blower fan ON signal to the BCM.

- BCM transmits the A/C ON signal and blower fan ON signal to ECM via CAN communication line. Refer to EC"CAN COMMUNICATION : System Description"

- ECM judges the conditions of each sensor (Refrigerant pressure sensor signal, accelerator position signal, etc.), and transmits the A/C compressor request signal to IPDM E/R via CAN communication line.

- By receiving the A/C compressor request signal from ECM, IPDM E/R turns the A/C relay to ON, and activates the compressor. Refer to PCS "RELAY CONTROL SYSTEM : System Description" or PCS "RELAY CONTROL SYSTEM : System Description"

CONTROL BY THERMO CONTROL AMP.

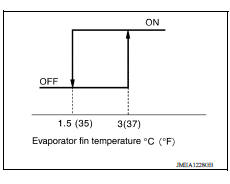

Low Temperature Protection Control

- When thermo control amp. detects that evaporator fin temperature

is 1.5C (35F) or less, thermo control amp. switches A/C ON signal

to OFF and stops the compressor.

When the evaporator fin temperature returns to 3C (37F) or more, the compressor is activated.

CONTROL BY ECM

Refrigerant Pressure Protection

The refrigerant system is protected against excessively high- or low-pressures by the refrigerant pressure sensor, located on the liquid tank on the condenser. The refrigerant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM. If the system pressure rises above or falls below the following values, the ECM requests the IPDM E/R to de-energize the A/C relay and disengage the compressor.

- 3.12 MPa (31.82 kg/cm2, 452.4 psi) or more (When the engine speed is less than 1,500 rpm)

- 2.74 MPa (27.95 kg/cm2, 397.3 psi) or more (When the engine speed is 1,500 rpm or more)

- 0.14 MPa (1.43 kg/cm2, 20.3 psi) or less

Compressor Oil Circulation Control

When the engine starts while the engine coolant temperature is 56C (133F) or less, ECM activates the compressor for approximately 6 seconds and circulates the compressor oil once.

Air Conditioning Cut Control

When the engine is under a high load condition, the ECM transmits an A/C relay OFF request to IPDM E/R, and stops the compressor. Refer to EC "AIR CONDITIONING CUT CONTROL : System Description".

Manual air conditioning system : Door Control

SWITCHES AND THEIR CONTROL FUNCTIONS

1. Intake door 2. Blower motor 3. Evaporator

4. Air mix door 5. Heater core 6. Foot door

7. Ventilator and defroster door

Fresh air intake

Fresh air intake  Recirculation

air

Recirculation

air  Defroster

Defroster

Center ventilator

Center ventilator  Side

ventilator

Side

ventilator

Rear foot*

Rear foot*

*: With rear foot duct

AIR DISTRIBUTION

With rear foot duct

Without rear foot duct

OPERATION

Switch Name and Function

CONTROLLER

1. Fan control dial (fan switch) 2. MODE dial 3. Intake lever 4. Temperature control dial 5. A/C switch

SWITCH OPERATION

| Fan control dial (fan switch) | Fan speed can be adjusted within a range from 1st to 4th. |

| MODE dial | Mode position is selected to an optimal position by operating this dial. |

| Intake lever | The air inlet changes REC-FRE each time by operation this lever. |

| Temperature control dial | The setting temperature can be selected to an optimum temperature by operating this dial. |

| A/C switch | The compressor control (switch indicator) is turned ON-OFF each time by pressing this switch while the blower motor is activated. |

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

| Direct Diagnostic Mode | Description |

| ECU identification | The BCM part number is displayed. |

| Self Diagnostic Result | The BCM self diagnostic results are displayed. |

| Data Monitor | The BCM input/output data is displayed in real time. |

| Active Test | The BCM activates outputs to test components. |

| Work support | The settings for BCM functions can be changed. |

| Configuration | - The vehicle specification can be read and saved. - The vehicle specification can be written when replacing BCM. |

| CAN DIAG SUPPORT MNTR | The result of transmit/receive diagnosis of CAN communication is displayed. |

SYSTEM APPLICATION

BCM can perform the following functions.

AIR CONDITIONER

AIR CONDITIONER : CONSULT Function (BCM - AIR CONDITIONER)

DATA MONITOR

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

| Direct Diagnostic Mode | Description |

| ECU identification | The BCM part number is displayed. |

| Self Diagnostic Result | The BCM self diagnostic results are displayed. |

| Data Monitor | The BCM input/output data is displayed in real time. |

| Active Test | The BCM activates outputs to test components. |

| Work support | The settings for BCM functions can be changed. |

| Configuration | - The vehicle specification can be read and saved. - The vehicle specification can be written when replacing BCM. |

| CAN DIAG SUPPORT MNTR | The result of transmit/receive diagnosis of CAN communication is displayed. |

SYSTEM APPLICATION

BCM can perform the following functions.

AIR CONDITIONER

AIR CONDITIONER : CONSULT Function (BCM - AIR CONDITIONER)

SYSTEM APPLICATION

ECU DIAGNOSIS INFORMATION

BCM, ECM, IPDM E/R

List of ECU Reference

| ECU | Reference |

| BCM (with Intelligent Key system) | BCS"Reference Value" |

| BCS "Fail-safe" | |

| BCS "DTC Inspection Priority Chart" | |

| BCS "DTC Index" | |

| BCM (without Intelligent Key system) | BCS "Reference Value" |

| BCS "Fail-safe" | |

| BCS "DTC Inspection Priority Chart" | |

| BCS "DTC Index" | |

| ECM | EC "Reference Value" |

| EC "Fail Safe" | |

| EC "DTC Inspection Priority Chart" | |

| EC "DTC Index" | |

| IPDM E/R (with Intelligent Key system) | PCS "Reference Value" |

| PCS "Fail-safe" | |

| PCS "DTC Index" | |

| IPDM E/R (without Intelligent Key system) | PCS "Reference Value" |

| PCS "Fail-Safe" | |

| PCS "DTC Index" |

WIRING DIAGRAM

MANUAL AIR CONDITIONING SYSTEM

Wiring Diagram

MANUAL HEATER SYSTEM

Wiring Diagram

BASIC INSPECTION

Diagnosis and repair workflow

Workflow OVERALL SEQUENCE DETAILED FLOW 1.INTERVIEW CUSTOMER Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunctio ...

Other materials:

Engine assembly

Exploded View

1. Engine mounting (RH) stay 2. Engine mount (RH) stay 3. Engine mounting

insulator (RH)

4. Rear engine mounting bracket 5. Rear torque rod 6. Engine mounting bracket

(LH)

7. Engine mounting bracket (LH) 8. Engine mounting insulator (LH) 9. Mass damper

A. Front mark B. Tra ...

Exhaust system

Exploded View

1. Heated oxygen sensor 2 2. Catalyst cover (upper) 3. Seal bearing

4. Catalyst cover (lower) 5. Spring 6. Spring

7. Mounting rubber 8. Main muffler 9. Ring gasket

10. Center muffler 11. Mounting rubber 12. Seal bearing

13. Exhaust front tube

Removal and Installation

WARNIN ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0153

Precautions

Precautions