Nissan Versa Sedan Service ManualEngine » Engine mechanical (EM) » Camshaft

Nissan Versa Sedan Service ManualEngine » Engine mechanical (EM) » Camshaft

Inspection

Inspection

INSPECTION AFTER REMOVAL

Oil Filter

- Check that there is no foreign material on the oil filter (1) and check it for clogging.

- Check the oil filter for damage.

- If there is some damage, replace the oil filter, the plug, and the washer as a set.

CAUTION:

Do not reuse the washer.

Camshaft Runout

1. Put Vblock on a precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter from the other four locations.

- Set a dial indicator vertically to No. 3 journal.

- Turn camshaft to one direction, and measure the camshaft runout on the dial indicator. (Total indicator reading)

4. If it exceeds the limit, replace camshaft.

Camshaft Cam Height

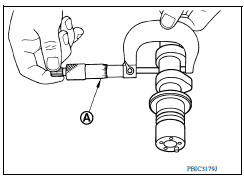

1. Measure the camshaft cam height with a micrometer (A).

2. If wear exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

CAMSHAFT JOURNAL DIAMETER

Measure the outer diameter of camshaft journal with a micrometer (A).

CAMSHAFT BRACKET INNER DIAMETER

- Tighten camshaft bracket bolts to the specified torque. Refer to "INSTALLATION" for the tightening procedure.

- Measure inner diameter (b) of camshaft bracket with a bore gauge (A).

CAMSHAFT JOURNAL OIL CLEARANCE

- (Oil clearance) = (Camshaft bracket inner diameter) - (Camshaft journal diameter)

- If it exceeds the limit, replace either or both camshaft and cylinder head.

NOTE:

Camshaft brackets cannot be replaced as single parts, because they are machined together with cylinder head. Replace whole cylinder head assembly.

Camshaft End Play

- Install camshaft in cylinder head.

- Install a dial indicator (A) in thrust direction on front end of

camshaft.

Measure the camshaft end play on the dial indicator when camshaft is moved forward/backward (in direction to axis).

- Measure the following parts if out of the standard.

- Dimension "A" for cylinder head No. 1 journal bearing

Standard : 4.000 4.030 mm (0.1574 0.1586 in)

- Dimension "B" for camshaft thrust

Standard : 3.877 3.925 mm (0.1526 0.1545 in)

- Refer to the standards above, and then replace camshaft and/ or cylinder head.

Camshaft Sprocket Runout

1. Put Vblock on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter from the other four locations.

2. Measure the camshaft sprocket runout with a dial indicator (A).

(Total indicator reading)

Limit : 0.15 mm (0.0059 in)

- If it exceeds the limit, replace camshaft sprocket.

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

- If anything above is found, replace valve lifter.

Valve Lifter Clearance

VALVE LIFTER OUTER DIAMETER

- Measure the outer diameter of valve lifter with a micrometer (A).

VALVE LIFTER HOLE DIAMETER

Measure the diameter of valve lifter hole of cylinder head with an inside micrometer (A).

VALVE LIFTER CLEARANCE

- (Valve lifter clearance) = (Valve lifter hole diameter) - (Valve lifter outer diameter)

- If out of the standard, referring to the each standard of valve lifter outer diameter and valve lifter hole diameter, replace either or both valve lifter and cylinder head.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket Oil Groove

CAUTION:

- Perform this inspection only when DTC P0011 or P0014 is detected in selfdiagnostic results of CONSULT and it is directed according to inspection procedure of EC section.

- Check when engine is cold so as to prevent burns from the splashing engine oil.

NOTE:

This section provides the inspection method of oil passage of cam sprocket on the intake side. For oil passage on the exhaust side, the inspection procedure must be changed as instructed below:

Step 3 : Remove exhaust valve timing control solenoid valve. Refer to EM56, "Exploded View".

Step 4 : Crank engine, and then check that engine oil comes out from exhaust valve timing control solenoid valve hole (A). End crank after checking.

Step 5 Perform the following inspection if engine oil does not come out from exhaust valve timing control solenoid valve oil hole of the cylinder head.

- Remove oil filter, and then clean it. Refer to EM56, "Exploded View".

- Clean oil groove between oil strainer and exhaust valve timing control solenoid valve. Refer to EM56, "Exploded View".

Step 6 : Remove components between exhaust valve timing control solenoid valve and camshaft sprocket (EXH), and then check each oil groove for clogging.

- Check engine oil level.

- Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

a. Release the fuel pressure.

b. Remove intake manifold.

c. Disconnect ignition coil and injector harness connectors.

- Remove intake valve timing control solenoid valve.

- Crank engine, and then check that engine oil comes out from intake valve timing control solenoid valve hole (A). End crank after checking.

(1) : Plug

:Engine front

:Engine front

WARNING:

- Be careful not to touch rotating parts (drive belts, idler pulley, and crankshaft pulley, etc.).

CAUTION:

- Prevent splashing by using a shop cloth to prevent injury from splashing engine oil and so as to prevent engine oil contamination.

- Use a shop cloth to prevent engine oil from being splashed to engine and vehicle. Especially be careful not to spill engine oil to rubber parts of drive belts, engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

5. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid valve oil hole of the cylinder head.

- Remove oil filter, and then clean it.

- Clean oil groove between oil strainer and intake valve timing control solenoid valve.

6. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT), and then check each oil groove for clogging.

- Clean oil groove if necessary.

7. After inspection, installation of components is in the reverse order of removal