Nissan Versa (N17): Fuel level sensor signal circuit

Description

The fuel level sensor unit and fuel pump detects the approximate fuel level in the fuel tank and transmits the fuel level signal to the combination meter.

Component Function Check

1.COMBINATION METER INPUT SIGNAL

1. Select METER/M&A on CONSULT.

2. Using FUEL METER of DATA MONITOR, compare the DATA MONITOR value with the

fuel gauge position.

Does monitor value match fuel gauge reading?

YES >> Inspection End.

NO >> Replace combination meter. Refer to MWI "Removal and Installation".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI "Wiring Diagram".

1.CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Check combination meter and fuel level sensor unit terminals (meter-side and harness-side) for poor connection.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace terminals or connectors.

2.CHECK FUEL LEVEL SENSOR UNIT CIRCUIT

1. Disconnect combination meter harness connector M82 and fuel level sensor unit and fuel pump harness connector B44.

2. Check continuity between combination meter harness connector M82 terminal

6 and fuel level sensor unit

and fuel pump harness connector B44 terminal 2.

3. Check continuity between fuel level sensor unit and fuel pump harness

connector B44 terminal 2 and

ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair harness or connector.

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Check continuity between combination meter harness connector M82 terminal

24 and fuel level sensor

unit and fuel pump harness connector B44 terminal 5.

2. Check continuity between fuel level sensor unit and fuel pump harness

connector B44 terminal 5 and

ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair harness or connector.

4.CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and verify the float arm does not interfere or bind with the internal components in the fuel tank.

Is the inspection result normal?

YES >> Inspection End.

NO >> Install the fuel level sensor unit properly.

Component Inspection

1.REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to FL "Removal and Installation".

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT

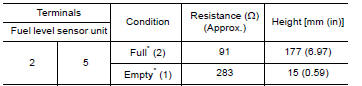

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is in contact with stopper.

Is inspection result OK?

YES >> Inspection End.

NO >> Replace fuel level sensor unit and fuel pump. Refer to

FL "Removal and Installation".

Washer fluid level switch circuit

Description Transmits the washer fluid level switch signal to the combination meter. Diagnosis Procedure Regarding Wiring Diagram information, refer to MWI "Wiring Diagram". 1.CHECK WA ...

Other materials:

P074C Unable to engage 4GR

Description

This malfunction is detected when the A/T does not shift into 4GR position as

instructed by TCM. This is not

only caused by electrical malfunction (circuits open or shorted) but by

mechanical malfunction such as control

valve sticking, improper solenoid valve operation, etc.

DTC ...

Lock-up control

LOCK-UP CONTROL : System Description

SYSTEM DIAGRAM

DESCRIPTION

Controls for improvement of the transmission efficiency by engaging the

torque converter clutch in the

torque converter and eliminating slip of the converter. Achieves comfortable

driving with slip control of the

t ...

Categories

- Manuals Home

- Nissan Versa Owners Manual

- Nissan Versa Service Manual

- Video Guides

- Questions & Answers

- External Resources

- Latest Updates

- Most Popular

- Sitemap

- Search the site

- Privacy Policy

- Contact Us

0.0057

Power supply and ground circuit

Power supply and ground circuit