Nissan Versa Sedan Service ManualSuspension » Front suspension (FSU) » Front coil spring and strut

Nissan Versa Sedan Service ManualSuspension » Front suspension (FSU) » Front coil spring and strut

Disassembly and Assembly

Disassembly and Assembly

DISASSEMBLY

CAUTION: Do not damage strut assembly piston rod when removing components from strut assembly.

- Remove strut mounting insulator.

- Install Tool (A) to strut assembly and secure it in a vise.

Tool number : ST35652000 ( - )

CAUTION: When installing the Tool to strut assembly, wrap a shop cloth around strut to protect from damage.

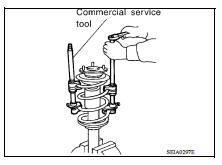

- Using a suitable tool, compress coil spring between spring upper

seat and lower seat (strut assembly) until coil spring is free.

CAUTION: Be sure the tool is securely attached to the coil spring before compressing coil spring.

- Check coil spring with a spring compressor between spring upper seat and lower seat (strut assembly) is free. And then remove piston rod lock nut while securing the piston rod tip so that piston rod does not turn.

- Remove strut mounting bearing, spring upper seat, and bound bumper as a set.

- Remove bound bumper from spring upper seat.

- After removing coil spring with a spring compressor, then gradually

release a spring compressor.

CAUTION: Loosen while making sure coil spring attachment position does not move.

- Remove the Tool from strut.

Tool number : ST35652000 ( - )

9. If necessary, remove strut mounting bearing (1) from spring upper seat (2), using a Tool (A).

Tool number : KV10106700 ( - )

CAUTION: Do not disassemble the strut mounting bearing unless damage exists.

10. Perform inspection after disassembly. Refer to FSU "Inspection and Adjustment".

INSPECTION AFTER DISASSEMBLY

Strut Inspection

Check the following:

- Strut for deformation, cracks or damage, and replace it if necessary.

- Piston rod for damage, uneven wear or distortion, and replace it if necessary.

- For oil leakage, and replace it if necessary.

Strut Mounting Insulator and Rubber Parts Inspection

Check strut mounting insulator for cracks and rubber parts for wear. Replace it if malfunction is detected.

Coil Spring Inspection

Check coil spring for cracks, wear or damage, and replace it if necessary.

ASSEMBLY

1. Install Tool (A) to strut and secure it in a vise.

Tool number : ST35652000 ( - )

CAUTION: When installing the strut attachment to strut assembly, wrap a shop cloth around strut to protect from damage.

2. Apply soapy water to bound bumper.

CAUTION: Do not use machine oil.

3. Insert bound bumper into spring upper seat.

4. Compress coil spring using a spring compressor (commercial service tool), and install it onto strut assembly.

CAUTION:

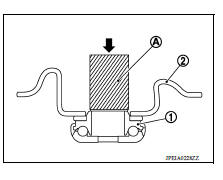

- Face tube side of coil spring (1) downward. Align the lower end (A) to lower seat (strut assembly) (2).

- Be sure a compressor is securely attached to coil spring.

Compress coil spring.

5. Install strut mounting bearing, spring upper seat, and bound bumper as a set.

6. Secure piston rod tip so that piston rod does not turn, then tighten piston rod lock nut with specified torque.

7. Gradually release a spring compressor, and remove coil spring.

CAUTION: Loosen while making sure coil spring attachment position does not move.

8. Remove the Tool (A) from strut assembly.

Tool number : ST35652000 ( - )

9. Install strut mounting insulator.